Explore the World's TopLab

Earlier in May, more than 20 authoritative media representatives and industry experts from Europe visited Yutong, embarking on a "Green Power Value Exploration Journey" to Yutong Bus Brand Experience Center, New Energy Manufacturing Base, and Engineering Testing Center. As global transportation transitions towards electrification, the public is still concerned about the maturity and safety of electric vehicle technology.

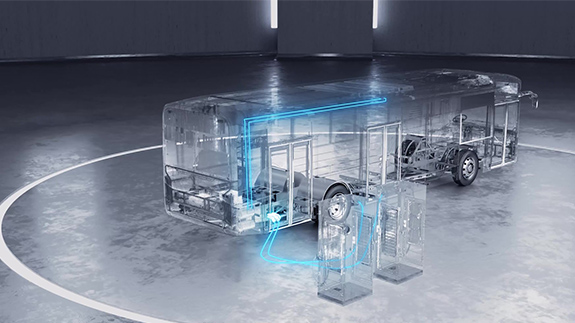

As a global leader in new energy commercial vehicles, Yutong is well aware of the importance of safety for passengers. During the visit of the European media group, Yutong conducted a series of battery safety tests in the world-class electric vehicle laboratory, demonstrating its outstanding safety and stability in extremely cold weather at -30°C, rapidly spreading 1300°C fires and under 2 meters of water.

Four Challenges to Bus Safety

Ensuring public safety within the public transportation sector is a multifaceted challenge. Yutong Bus conducts rigorous testing in the TopLab, primarily focusing on four areas.

1. Waterproof Safety Test

In Yutong's laboratories, waterproof safety tests are meticulously designed to emulate the conditions of urban waterlogging. These tests involve submerging motors and batteries at various depths to evaluate their sealing capabilities. The findings were remarkable: even after enduring a 72-hour submersion at a depth of 2 meters, the motors continued to function flawlessly, leaving a profound impact on the visitors.

Watch the whole test at:

2. External Fire Test

Yutong Laboratory's external fire test demonstrated the exceptional safety and resilience of thebatteries when exposed to severe conditions like gasoline-induced fires. The test, which simulated both direct and indirect fire exposures at 1300°C for 2 hours, proved the material's fire resistance and insulation capabilities.

The electric busbatteries featured an advanced three-layer fireproof system that successfully contained external flames and safeguarded the internal battery cells. Throughout the testing process, it was evident that the spread of external flames was effectively thwarted, thereby achieving operational safety under a variety of extreme conditions and perpetuating Yutong's legacy of safety.

Watch the whole test at:

3. Needle Puncturing Test

In Yutong Bus's battery safety testing, technicians also conducted a rigorous simulation test to evaluate the safety of the battery cells. A high-temperature resistant steel needle with a diameter of 8 mm was used in the test, puncturing the geometric center of the battery at a speed of 25±5 mm/s from a direction perpendicular to the battery poles, and the needle was kept inside the cell for an hour.

The test results were impressive: under such harsh conditions, the cell neither exploded nor caught fire, demonstrating its excellent safety and reliability. This achievement not only highlights Yutong Bus's leading position in battery safety technology but also underscores our unwavering commitment to producing batteries that meet the highest safety standards.

Through this test, Yutong Bus has showcased the high safety performance of our electric buses to the public, ensuring the safety and peace of mind of passengers. This not only strengthens consumer confidence in the safety of electric buses but also demonstrates Yutong Bus's corporate responsibility to prioritize passenger safety while promoting new energy transportation solutions.

Watch the whole test at:

4. Nitrogen Protection Test

In Yutong Bus's nitrogen protection tests, we showcased our pioneering nitrogen protection system for batteries, which offers multiple layers of protection. During the test, the performance of batteries with and without nitrogen protection was compared under forced heating conditions. The results revealed that the unprotected batteries eventually exploded and flamed, highlighting serious safety hazards.

In contrast, Yutong's nitrogen-protected batteries remained stable under the same conditions, with no explosion, demonstrating superior safety performance. The advantages of this full-time domain nitrogen protection system lie in its international innovation and its ability to ensure that batteries do not catch fire or explode during thermal runaway. Additionally, the system addresses insulation issues in high-temperature and high-humidity environments and provides early warnings about the risk of battery water ingress.

This test underscores Yutong's unwavering commitment to battery safety, enhancing the reliability of the batteries and providing users with a greater sense of safety. Through these innovative safety measures, Yutong Bus has once again demonstrated leadership in raising the safety standards of buses and offers additional safety assurance to passengers and operators.

Watch the whole test at:

Media Comments on Yutong

The European media, invited to this exploration journey, deeply and comprehensively experienced Yutong's long-standing commitment to safety philosophy and reliable quality. They expressed their praise in the videos posted on Yutong's official Facebook page:

● “All four tests were very impressive. And the test, particularly on the battery, was really impressive because it’s very safe.”

● “The water test. That’s very cool! Yutong Bus is one of the biggest manufacturers in the world. I have never seen a plant so big.”

● “The external fire test is very persuasive. Seeing the real testing in very hard conditions of batteries to test their safety is very important. Because safety is one of the main focuses of customers and buyers of electric buses.”

Conclusion

In conclusion, Yutong Bus's state-of-the-art laboratory has left a profound impression on the European media, showcasing our unwavering commitment to innovation, safety, and quality. Through a series of rigorous and impressive tests, such as the external fire test and the nitrogen protection test, we have demonstrated the exceptional safety features and reliability of Yutong electric buses.

Previous Industry-insights

Subscribe Now

Get updates you care about.

Submit