Tech Knowhow of Yutong Power Battery-Environmental Protection

Facing the dual challenges of global climate crisis and environmental pollution, batteries are becoming the key for reducing carbon emissions and realizing green economic transformation for high efficiency and environmental protection characteristics. With the rapid popularization of new energy vehicles, power batteries have become their core components, helping the world find a balance between transportation development and environmental protection.

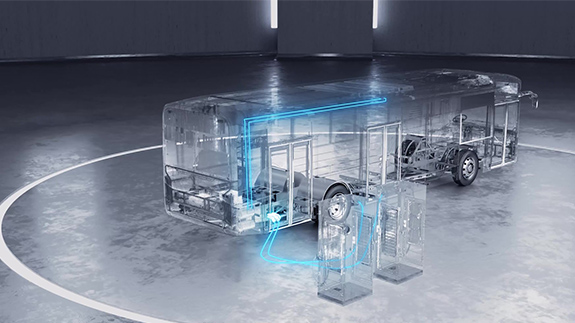

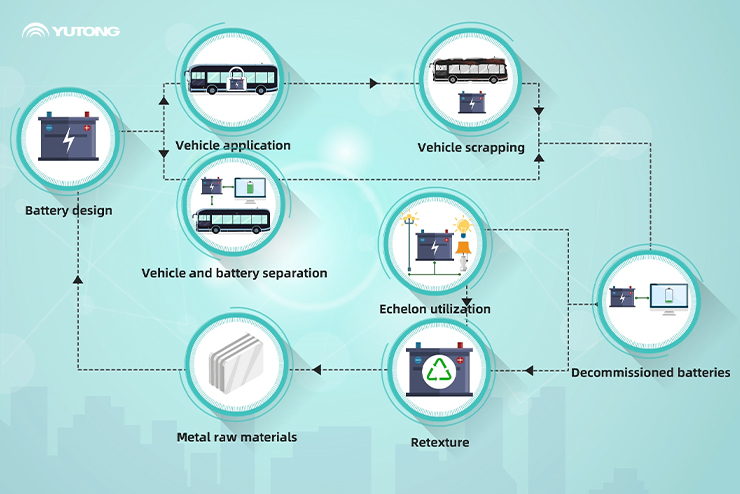

Power batteries must go through strict life cycle management from production to recycling. First of all, at the beginning of battery design and manufacturing, materials are strictly selected for environmental protection. Yutong uses lithium iron phosphate battery. The positive electrode is lithium iron phosphate (LiFePO4) and the negative electrode is graphite, which does not contain heavy metals such as cobalt, manganese, nickel and other harmful substances, and has no pollution to the environment. Secondly, the waste pollutants generated in the battery production process will be controlled from the source. The process goes through identification, classification, collection, storage, transfer and disposal to cross-validation of various equipment and institutions. Finally, in the whole process of waste battery disposal, centralized "physical treatment" and "chemical regeneration" methods will also be adopted to extract new materials from them for recycling of batteries, thus realizing a complete full life cycle closed loop of batteries. The battery of Yutong bus has an ultra-long service life up to 10 years and 1,000,000 km. It will still be used for energy storage in cascade until it attenuates to the extent that it cannot be used on the bus. After dismantling and reorganization, its application scenarios also include household energy storage, low-speed vehicles, solar street lamps, mobile power supply and standby power supply for tower base stations, so as to realize resource reuse.

Yutong works together with customers to create an ecological closed loop of "battery use- recycling-cascade utilization - regeneration treatment", solving the problem of rapid early battery attenuation, promoting battery manufacturers to carry out recycling and cascade utilization of power batteries for new energy buses. Yutong has developed a sustainable battery value chain, taking environmental protection and green social responsibility, and helping achieve the global carbon neutrality goal.

Yutong has established strategic cooperation with the upstream and downstream of the industrial chain. At present, it has 14 recycling bases in China, covering the Yangtze River Delta, Pearl River Delta and central China, and gradually expanding to the whole world.

At present, Yutong has sold 190,000 new energy buses in total, reducing fuel consumption by about 8.8 billion liters, saving 1.4 billion cubic meters of gas and reducing carbon emissions by 26.5 million tons, which is equivalent to planting trees of 130,000 hectares. In the future, Yutong will fully empower the high-quality development of public transportation with innovative technology, and devote itself to providing more environmentally friendly and efficient transportation solutions, thus contributing to global sustainable development.

Previous Industry-insights

Subscribe Now

Get updates you care about.

Submit