Electric Buses vs Diesel Buses: A Comparative Analysis of Life-Cycle Operating Costs

Public transportation is the key to saving energy and reducing greenhouse gas (GHG) emissions. According to the World Resources Institute, buses and trains can reduce GHG emissions by up to two-thirds per passenger per kilometer compared to private cars.

The UN's latest Climate Action also states that shifting more trips to public transit is "essential" to curbing climate change. [1]

This article further guides you about the costs of diesel vs. electric buses and the average energy consumption of a bus to help you make a wise decision.

Overview of Diesel Buses

Diesel buses are typically diesel engine vehicles that are powered by diesel engines. They use diesel as fuel and work on the principle of compression ignition. They have been the backbone of public transportation for years due to their reliability. These buses can easily carry large loads and travel long distances, whether it's urban travel or intercity routes.

Working Principle of Diesel Buses

The working principles of diesel buses are pretty simple. First, the diesel engine draws in air through an intake system, where it is filtered to remove debris.

The engine then uses a piston to compress air, increasing temperature. At the peak of compression, diesel fuel is injected into the cylinder. When the high-temperature air contacts with diesel, the diesel will be ignited to create a small explosion.

This explosion moves the piston, converting heat energy into mechanical energy, which is then transferred to the bus wheels via the crankshaft and transmission system. Hence, the bus starts moving.

Disadvantages of Diesel Buses

Despite their widespread popularity, diesel buses have their cons, such as:

● Environmental Impact: Unfortunately, diesel bus exhaust includes fine carbon particles and a mixture of toxic and carcinogenic gases. Statistics reveal that even modern diesel buses produce 10 times more air pollution than heavy trucks and other buses. [2] This puts the environment as well as human health at risk, causing lung cancers and other breathing issues.

● High Cost: Diesel engines and fuel systems are complex in structure and have many parts, requiring regular replacement of oil, filters and other wear parts, which is frequent and expensive to maintain. To meet environmental regulations, diesel buses are equipped with complex emission control systems, such as diesel particulate filters (DPF) and selective catalytic reduction (SCR) systems. These systems not only increase the initial cost of the vehicle, but also require regular maintenance and replacement, and may increase repair costs due to breakdowns. In addition, the price of diesel fuel itself is highly volatile, leading to higher operating costs in the long term and financial pressure.

Full Life Cycle Cost Analysis and Calculation

Here's a detailed cost analysis of both electric and diesel buses:

Well, diesel costs come at a relatively small upfront cost. On the contrary, an e-bus may be more expensive than a standard diesel option. (price may fluctuate depending upon the order and other technicalities). [3] The battery cost of electric buses is a major part of the acquisition cost, but with technological advances, the battery cost is decreasing. In addition, many governments are providing acquisition subsidies for new energy buses, which has reduced the acquisition cost of electric buses to a certain extent.

Electric buses have a leading edge in terms of operating costs. Traditional diesel buses consume more fuel per mile, while electric buses have lower electricity costs per mile, meaning they save on high fuel costs. According to a survey of actual operations of two different vehicles, electric buses offer significant cost savings. Specifically, electric buses cost nearly 80% less than diesel buses, thanks to their lower energy consumption and efficient interior components. [4]

Over time, buses wear and tear due to the rugged road conditions and consistently being on the road. Therefore, it's necessary to maintain them regularly and check all their essential components to ensure the buses serve you in the long run.

Traditional diesel buses rely mainly on mechanical braking systems, where brake pads and discs wear out faster. What’s more, their oil, filters, and other fluids need to be replaced regularly, requiring more frequent replacement and maintenance and higher costs for consumables.

According to statistics from the American Public Energy Organization, electric buses cost much less to maintain than diesel buses. [5] The power system of electric buses is relatively simple, consisting mainly of motors, batteries and electric control systems. Due to the lack of complex mechanical components (e.g., pistons, crankshafts, etc.) found in traditional internal combustion engines, the power system of an electric bus requires relatively little routine maintenance.

Environmental Impact

The environmental impact of diesel buses is also way higher than that of electric buses. It makes a loud noise and a lot of greenhouse gases that adversely affect the environment as well as public health.

In contrast, electric buses, like the Yutong E12Pro, work without causing noise pollution. They also release 90% less GHG than traditional fuel buses, showcasing a commitment to providing sustainable travel solutions globally. [6]

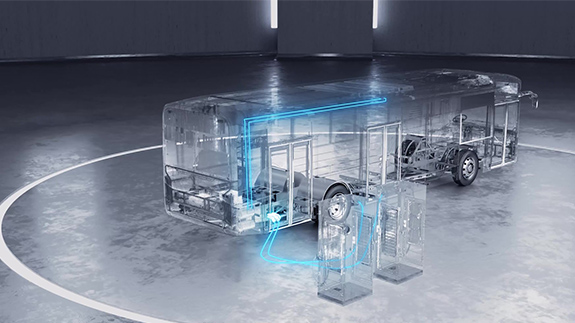

Overview of the Yutong E12Pro

Yutong electric buses, especially the E12Pro, have solutions to the concerns associated with diesel vehicles. Equipped with advanced YEA technology and the Yutong Electric Safety Standard (YESS), the Yutong E12Pro electric bus is fireproof and waterproof. Equipped with a 422 kWh lithium iron phosphate battery, the E12Pro consumes less energy than a diesel vehicle, emits less carbon, and is environmentally friendly and efficient. The integrated electric defrost, heating and high-voltage power distribution system provides a stylish design with a wide driving field of vision, while the safety monitoring system and IP68 protection ensure the safety of the motor, battery and electric control.

Conclusion

Yutong Bus with its advanced battery technology and efficient energy management system, provides a green and economical solution for urban public transportation. These new energy vehicles are favored for their robust internal components, high-efficiency energy consumption brought by YEA technology, and safe and environmentally friendly ergonomic design.

With the advancement of electric technology, future electric buses will achieve longer driving ranges and faster charging speeds, further reducing operational costs and enhancing passenger experience. Moreover, electric vehicles will become more intelligent, integrating autonomous driving and IoV technology, to promote green travel and the development of smart cities.

References:

[1] https://climatechangeresources.org/learn-more/transportation/public-transport/

[2] https://www.theguardian.com/environment/2017/jan/06/diesel-cars-are-10-times-more-toxic-than-trucks-and-buses-data-shows

[3] https://www.thecooldown.com/green-home/electric-bus-cost-cheaper/

[4] https://www.govtech.com/workforce/electric-buses-are-not-only-clean-but-less-costly-to-run.html

[5] https://www.publicpower.org/periodical/article/electric-buses-mass-transit-seen-cost-effective

[6] https://blog.ucsusa.org/jimmy-odea/electric-vs-diesel-vs-natural-gas-which-bus-is-best-for-the-climate/

Previous Industry-insights

Subscribe Now

Get updates you care about.

Submit