Exploring the Safety, Endurance and Performance of Yutong's Next-Gen EV Batteries

The electric bus battery, as the core component, is a crucial indicator to evaluate the electric vehicles' performance while bearing the significant responsibility of powering vehicles forward.

With the popularization of electric vehicles, safety has become the primary concern for consumers and the market. In addition, specific requirements such as driving range, charging speed, cost-effectiveness, and environmental-friendly performance are driving manufacturers to continuously explore and innovate to satisfy the rising demands of the market and consumers, as well as to address the challenges faced by current battery technology.

What are the challenges for electric bus batteries?

1. Battery Performance

At present, the energy density of electric bus batteries serves as one of the vital criteria for evaluating their performance. Higher energy density means that the electric bus battery can store more electricity within the same volume or weight, thereby significantly extending the range of electric vehicles.

However, increasing energy density is a challenging task. The mainstream lithium-ion batteries currently use graphite as the anode material, but its theoretical capacity is close to its limit. To improve energy density, researchers are exploring the use of alloy materials such as silicon and tin as anodes. These materials have higher theoretical capacities but also face issues such as poor cycle stability and volume expansion.

Solid-state batteries are considered a potential solution because they utilize solid electrolytes in place of liquid ones, offering higher safety and energy density. However, the ionic conductivity, interfacial stability, and manufacturing costs of solid-state electrolytes remain technical challenges that need to be overcome.

2. Battery Safety

Thermal protection and prevention of thermal runaway are vital priorities in electric bus battery safety. Under high-temperature conditions, the chemical reactions inside the battery will accelerate, generating more heat. If the thermal management system cannot effectively dissipate heat, the battery may overheat and cause thermal runaway.

When lithium batteries are overcharged, the battery structure may change, leading to a decline in performance and even creating safety hazards. Meanwhile, excessive voltage can decompose the electrolyte, generate a large amount of gas and increase the internal pressure of the battery. Once the pressure exceeds the tolerance limit of the battery casing, it may trigger an explosion.

Current thermal management systems often have difficulties in maintaining efficient heat dissipation under high loads, long-term operation, or extreme environments. The thermal conductivity of the material, the design of the heat dissipation structure, and the optimization of the thermal management algorithm are current challenges.

3. Battery Monitoring

The battery performance of electric buses will change over time and usage conditions, so the battery monitoring system is crucial to ensure safety and performance. Although current technologies have been able to achieve a certain degree of battery status monitoring, there are still some pain points and challenges:

Sensor accuracy and reliability: Sensors are the core components of battery monitoring systems, but their performance is easily affected by many factors, such as temperature, humidity, and electromagnetic interference. High-precision sensors are expensive, and their reliability and durability may gradually decline.

Algorithm complexity and adaptability: Battery status monitoring algorithms need to be able to adapt to different battery types, usage conditions, and aging processes, which increases the complexity of algorithm development. Developing such algorithms requires in-depth expertise and a large amount of experimental data.

Yutong's New EV Battery Technology

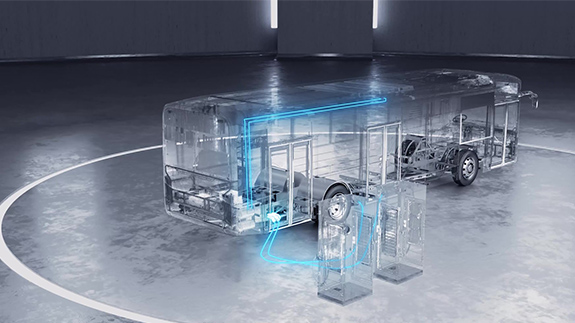

For the numerous challenges of EV battery, Yutong has leveraged its profound industry experience and forward-looking technical vision to introduce a new EV battery technology. The latest battery technology aims to comprehensively enhance the battery safety, lifespan, charging efficiency, and energy density, providing new value ideas for the new energy vehicle industry.

1. High Safety

Realizing the importance of battery safety, Yutong has prioritized safety in its new generation of electric bus battery solutions. Yutong adopts lithium iron phosphate battery to provide better thermal stability and longer cycle life.

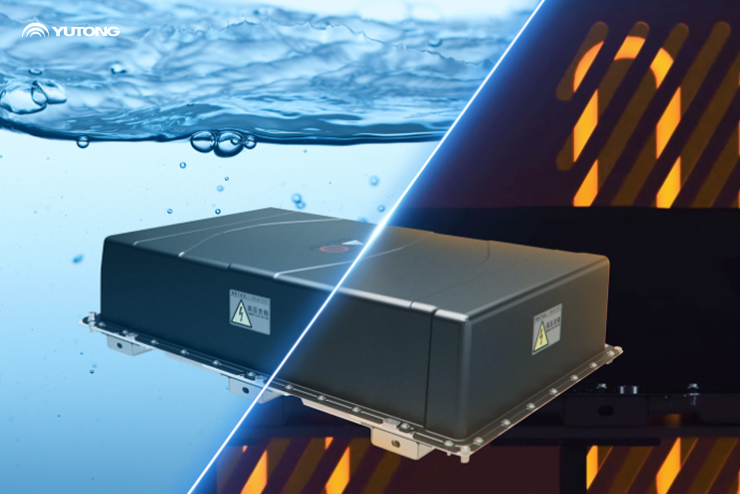

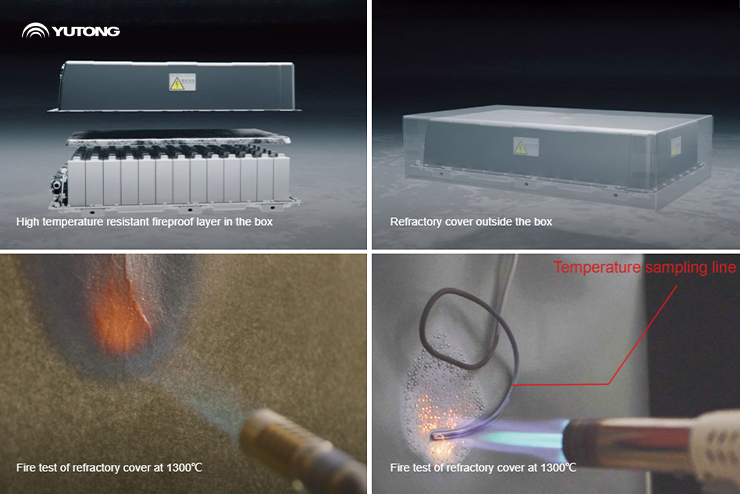

Yutong has developed robust protection technology. The extreme waterproof technology allows the batteries to be immersed in 1m deep water for 48 hours without water ingress. The innovative "sandwich" thermal insulation fireproof structure and the industry-first nitrogen protection system can isolate oxygen, and eliminate the risk of internal combustion, ensuring internal and external dual-isolation fire prevention at temperatures up to 1300°C for 2 hours.

Furthermore, the cage-like structure (with 1500MPa ultra-high strength steel) enhances the structural strength of the battery pack by 5 times, providing protection for the battery pack from all directions. The high-strength crash barriers and energy-absorbing components effectively absorb and disperse collision forces, safeguarding the battery pack from squeezing. This ensures that the battery pack can withstand bumping under various severe road conditions without damage.

In summary, Yutong batteries ensure high safety through the use of advanced materials, structural designs, and protective technologies.

2. Ultra-Long Lifespan

To extend the service life of electric bus batteries, Yutong adopts key technologies such as long-life cells, highly-reliable pack, and intelligent battery management. Meanwhile, Yutong also optimizes the battery PACK, which minimizes electric bus battery degradation through optimal layout and efficient thermal management.

The high-precision battery management system offers accurate monitoring of SOC (State of Charge), SOH (State of Health), and SOP (State of Power), ensuring effective management of the traction batteries throughout their lifecycle. With intelligent equalization technology, the differences between battery cells are automatically balanced, slowing down the attenuation.

3. Fast Charging

In view of the user's pain point of long charging times, Yutong has integrated efficient energy replenishment technology into its latest EV battery. Based on the current charging gun and charging port, Yutong pioneers a 600A independent dual-gun charging system. By optimizing and adapting the charging protocols, full compatibility is achieved, allowing dual-gun charging by any charger and doubling of charging capacity. In addition, a second gun can be inserted at any time to activate the dual-gun fast charging function during single-gun charging. The modular design allows the expansion of independent triple or quadruple charging functions.

4. High Energy Density

Yutong has leveraged the latest generation of high-energy-density battery cells, coupled with a highly integrated structural design, to achieve a 22% increase in the volumetric energy density of the battery pack, with the highest reaching 270Wh/L. Additionally, the mass energy density of the battery pack has improved by 9%, with the highest reaching 175Wh/kg. This high energy density allows for more electricity to be carried in the same space. Thus vehicles equipped with Yutong's high energy density batteries can better meet the demand for long-range travel. This innovation has also led to over 20% improvement in the space utilization rate of the vehicle, creating more room for passengers.

Yutong E11Pro's Battery System Triumphs in Saudi Arabian Extreme Heat Challenge

Nestled on the Arabian Peninsula, Saudi Arabia is characterized by an unforgiving tropical desert climate, featuring sweltering hot and arid summers, expansive sand dunes, and surface temperatures that soar past 60°C, posing formidable challenges for the operational capabilities of new energy electric vehicles.

However, just under such extreme conditions, the electric bus battery system of the Yutong E11Pro demonstrated its amazing high-temperature resistance and efficient energy management capabilities, successfully completing the high-temperature challenge.

At a surface temperature of 60°C in Saudi Arabia, the power consumption per 113km is only 0.74kWh/km, which fully demonstrates Yutong's strong strength in new energy technology and vehicle performance optimization.

Moreover, the energy consumption as low as 0.74 kWh/km further highlights Yutong's profound accumulation and innovative strength in electric bus battery energy-saving technology. This figure not only far surpasses the energy consumption levels of similar models in high-temperature environments but also significantly reduces vehicle operating costs, bringing users a more economical and environmentally friendly travel experience.

Conclusion

The outstanding performance of Yutong E11Pro in the high-temperature challenge in Saudi Arabia is a concentrated showcasing of Yutong's electric bus battery technology strength. It reflects Yutong's advanced capabilities across various aspects, including battery materials, battery management systems, and thermal management technologies. This achievement also underscores Yutong's deep understanding and accurate grasp of the new energy bus market.

Looking ahead, with Yutong's continuous cultivation and innovation in the field of battery technology, it will contribute more technical value to the development of the global new energy bus industry.

Previous Industry-insights

Subscribe Now

Get updates you care about.

Submit